The Trackball Mount

This is the part of the

trackball system that makes it track. The basic principle of the whole

works is to rest the spherical bottom of the telescope against an axle

that points at the celestial pole, and to rotate the axle so the sphere

turns once a day--exactly counteracting Earth's rotation. The axle is

mounted on a shuttle that can be moved along an arc, allowing adjustment

for the viewer's latitude.

This is the part of the

trackball system that makes it track. The basic principle of the whole

works is to rest the spherical bottom of the telescope against an axle

that points at the celestial pole, and to rotate the axle so the sphere

turns once a day--exactly counteracting Earth's rotation. The axle is

mounted on a shuttle that can be moved along an arc, allowing adjustment

for the viewer's latitude.

A sphere needs at least three points of support to hold it in place.

The axle is one of those points. I tried Teflon glides for the other

two, but at the incredibly slow speed of the ball's rotation, even

Teflon proved too sticky. Rather than track smoothly, the scope would

lurch forward, then pause, then lurch, then pause. Wax helped, but then

the ball's balance became supercritical. There's undoubtedly a happy

medium somewhere, but I gave up and went to roller bearings. That turned

out to be a good move. Roller bearings allow frictionless motion in the

right direction and resist motion in other directions, which actually

helps force the scope to track more precisely as well as more smoothly.

(No, they don't swivel, and yes, the ones in the photo are really angled

in the correct direction for my latitude. See below for details.)

A little experimentation showed that PVC pipe provided the right

amount of friction to keep the ball in place, yet let it slew smoothly

with just a light push.

The center disk is just a simple plywood round purchased pre-cut

from a lumber store. The legs were all cut from one 2' x 2' piece of

plywood. I cut notches in the legs so they would fit nice and tight over

the disk, then used chair-stiffening brackets underneath to stiffen them

even further (just visible under the left side of the disk). I still had

a bit of vibration, so I later added the turnbuckle tensioners.

I keep meaning to drill some holes in the disk for eyepiece storage

while I'm observing, but never got around to it. Good thing, actually.

The modification below would have blocked the eyepiece holes anyway.

A BETTER LEG BRACING

SYSTEM: The mount as built above allows some vibration, probably from

the long skinny legs and the relatively short triangles created by the

turnbuckles. I built a second trackball for my wife, Kathy, and braced

the legs with wooden gussets, and that really stiffened it up. The

settling time went from 6 seconds to 3. I'm also experimenting with

sorbothane anti-vibration pads under the feet. The right thickness will

get the settling time down to 1-2 seconds, at the cost of a little

sponginess to the entire scope when you slew it. Sorbothane knocks down

the short-period vibration almost completely, though. You can buy a

whole sheet of the stuff -- a lifetime supply -- at Edmund Scientific.

A BETTER LEG BRACING

SYSTEM: The mount as built above allows some vibration, probably from

the long skinny legs and the relatively short triangles created by the

turnbuckles. I built a second trackball for my wife, Kathy, and braced

the legs with wooden gussets, and that really stiffened it up. The

settling time went from 6 seconds to 3. I'm also experimenting with

sorbothane anti-vibration pads under the feet. The right thickness will

get the settling time down to 1-2 seconds, at the cost of a little

sponginess to the entire scope when you slew it. Sorbothane knocks down

the short-period vibration almost completely, though. You can buy a

whole sheet of the stuff -- a lifetime supply -- at Edmund Scientific.

I also made the drive axle a little larger in diameter and used

roller-blade bearings rather than the bic pen design on my first scope.

It's nearly frictionless, which allowed me to use a lighter-duty motor,

but otherwise the design is similar. I've described both axle designs

below.

The axle

The axle

The axle is pretty simple: On my first trackball I used a carriage

bolt, some washers, a Bic pen barrel, a hose, and a piece of PVC pipe. I

had to ream out the pipe to get the hose to fit.

The gear is from a hobby shop. It's the drive gear for a

radio-controlled car, and costs about $2.50. Drill out the hub so it

fits snugly over the pen barrel, and drill a couple of tiny holes in the

spokes for equally tiny brads to pin it to the pipe so it will actually

turn the axle instead of just spin in place. In the S&T

article I said to pin the gear to the hose, but I later realized there's

too much flex that way. Pin it to the pipe. (You could also glue it if

you want.)

Wax the bolt before you slip it inside the pen barrel. I just ran a

birthday candle up and down it a few times.

The bracket that holds the axle (see below) is a piece of 3/4" x

3/32" bar stock bent into a shallow "U" and screwed to a block of wood.

Leave room for the worm gear (a 3/8" bolt) to clear the bracket. (If you

use a different gear than what I used, you may need a different size

bolt to mesh with the teeth.)

The washers keep things from slipping apart and provide spacers so

the axle fits snugly in the bracket. Any play there will become slop in

declination when you're using the scope.

You can remove the lettering on the pipe with a simple rubber eraser.

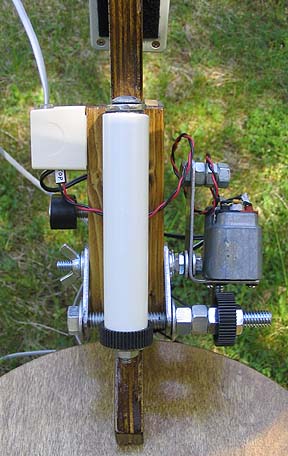

NEWER AXLE DESIGN: On my later axles

I used roller blade bearings instead of a Bic pen barrel. It's a little

more complicated, but well worth the trouble. The roller blade bearings

are nearly frictionless, which means you can use a smaller drive motor.

NEWER AXLE DESIGN: On my later axles

I used roller blade bearings instead of a Bic pen barrel. It's a little

more complicated, but well worth the trouble. The roller blade bearings

are nearly frictionless, which means you can use a smaller drive motor.

The copper tubing allows you to tighten the bolt without squeezing

the bearings together. The wooden dowel keeps the PVC pipe from buckling

under the weight of the telescope. (It's probably not necessary, but I

did it just in case.) The dowel is drilled out to a diameter a little

larger than the copper tube, so the dowel can rotate without rubbing on

the tubing. The tiny piece of copper tube is to keep the washers from

pushing the gear into the bearing and creating friction there. Drill out

the center of the gear so it doesn't touch the copper spacer (just like

the dowel doesn't touch the long piece of tubing). The gear is glued to

the outer (PVC) pipe. Do this after you assemble everything! You want

the gear to be absolutely centered. It shouldn't wobble at all when you

spin the axle, or the worm gear will tighten up on the high side and

loosen on the low side.

The washers are smaller than the bearing diameter and keep the

bearing faces from rubbing on the metal bracket that holds the whole

works in place. The PVC pipe had to be a little larger than the first

axle so it could hold the bearings. Even so I had to hollow out the

inside a bit to make them fit.

The motor

The motor

The ball has to turn once per day. If you have a 16" ball and a 7/8"

axle, that means your axle has to turn 18.28 times per day. A 50-tooth

drive gear means your worm gear needs to turn 914 times per day, or

0.635rpm. It's hard to find a motor that turns that slowly, so I made a

second worm gear that brought the motor speed up to 30 rpm. It's a lot

easier to find 12-volt DC motors in that range. I bought one that was

rated for 20-45 rpm so I could tweak the tracking speed quite a ways if

my calculations were off. (I got mine from Techmax,

which sells salvaged motors. Jameco

also has a good selection of new motors.)

You could undoubtedly use a step motor if you want. I went with a

simple DC gear motor because the circuitry is so much simpler. A

variable resister between the motor and the battery is all you really

need for a speed control. I got a little fancier, but not a whole lot

more so. (See circuit diagram below.)

I had to drill a hole in the second worm gear (i.e. another 3/16"

bolt) so it could fit over the motor shaft. I had a heck of a time

getting the hole centered until I realized I could put the bolt in a

drill press and lower it onto a stationary drill bit. Perfectly centered

hole! Epoxy it onto the motor shaft, and occasionally run the motor

while the glue is setting so you can detect (and correct) any wobble.

This worm should be as perfectly centered on the motor shaft as you can

get it. A little wobble won't matter, but too much will give you a

periodic tracking error.

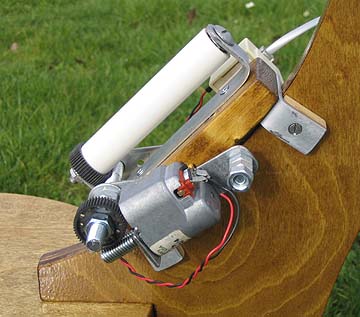

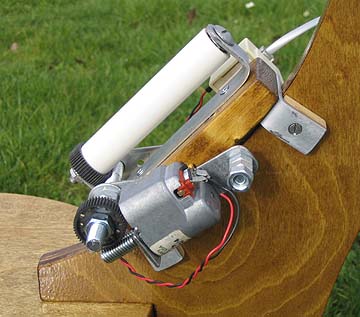

At

first I mounted the motor on a pivot so the weight of the motor would

hold the worm against the drive gear. That turned out not to be quite

enough weight, so I added a bolt and a few nuts for more weight on the

back of the motor. The pivot is on the same shaft that holds the other

worm gear's mounting brackets, which explains that thicket of nuts and

washers between the motor and the shuttle in the photo at right. Later I

gave up on that and added the spring-loaded idler below. It pushes the

motor's worm-gear shaft against the drive gear, and that works much

better than simply adding weight to the back.

At

first I mounted the motor on a pivot so the weight of the motor would

hold the worm against the drive gear. That turned out not to be quite

enough weight, so I added a bolt and a few nuts for more weight on the

back of the motor. The pivot is on the same shaft that holds the other

worm gear's mounting brackets, which explains that thicket of nuts and

washers between the motor and the shuttle in the photo at right. Later I

gave up on that and added the spring-loaded idler below. It pushes the

motor's worm-gear shaft against the drive gear, and that works much

better than simply adding weight to the back.

The worm gear that drives the PVC axle is held

into place by two more pieces of 3/4" x 3/32" bar stock. The angle of

the bar stock allows the worm to be adjusted up and down so it meshes

smoothly with the drive gear's teeth. I leave a little play in those

gears, because the weight of the telescope compresses the axle and

tightens them up.

The worm gear that drives the PVC axle is held

into place by two more pieces of 3/4" x 3/32" bar stock. The angle of

the bar stock allows the worm to be adjusted up and down so it meshes

smoothly with the drive gear's teeth. I leave a little play in those

gears, because the weight of the telescope compresses the axle and

tightens them up.

For my next two scopes I used tiny gear motors that I

also got from Techmax.

I was hoping these motors would run quieter than the first one, but

they don't. If anything, they're louder. I had to isolate them with

sorbothane to keep them from vibrating the whole mount like a big

speaker cabinet, but that did the trick and you can barely hear them now.

For my next two scopes I used tiny gear motors that I

also got from Techmax.

I was hoping these motors would run quieter than the first one, but

they don't. If anything, they're louder. I had to isolate them with

sorbothane to keep them from vibrating the whole mount like a big

speaker cabinet, but that did the trick and you can barely hear them now.

They do pull much less current, though (about 10-15 milliamps), so I

don't need a big battery to run the drive anymore. I run it on a set of

6 AA batteries in the black box Velcroed to the leg below the motor

shuttle, and figure I can get 20-30 nights of observing on a set of

batteries. I used the same basic electrical circuit as described below,

minus the momentary switches, which I never used on the original scope.

This system has one great advantage: it's all attached to the mount so

you have fewer things to carry. (And no hand controller wires to trip

over in the dark.)

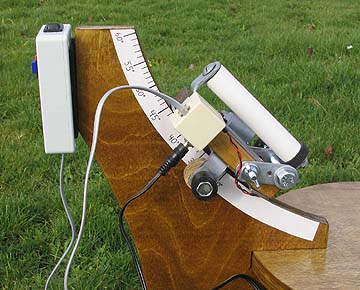

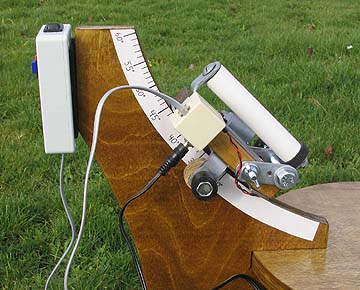

Latitude adjustment

Latitude adjustment

The latitude arc should be concentric with the sphere, so when you

move the axle shuttle up or down, the sphere stays put. You don't have

to be overly finicky about this; just get it close. (Don't use the same

radius as the sphere for this arc! The radius of the arc has to be

bigger than the radius of the sphere by the thickness of the

axle-shuttle combination.)

My shuttle uses two pads on the back side (visible four pictures

above) and one on this side with a screw-down clamp to hold it in place.  Use wood for the pads, rather

than rubber, or you'll get a lot of vibration in the scope. The clamp is

just a bolt with a wooden disk on the end of it. I got fancy and drilled

a hole in the end of the bolt so I could screw the disk onto it. It's

harder than I thought to tap threads into a bolt!

Use wood for the pads, rather

than rubber, or you'll get a lot of vibration in the scope. The clamp is

just a bolt with a wooden disk on the end of it. I got fancy and drilled

a hole in the end of the bolt so I could screw the disk onto it. It's

harder than I thought to tap threads into a bolt!

The knob is just a nut snugged up to the bolt head and both of them

covered with a piece of rubber hose.

I made a power distribution box out of an old telephone adapter.

Power goes into the box from a 12-volt battery below, then up the phone

cord to the hand controller and back to the motor.

The other two bearings

The other two bearings

The other two bearings are just idlers. They let the ball move

without friction in the direction of tracking motion, and they provide

just enough grip to constrain that motion to the angle you set them at.

They're made of PVC pipe couplings with rollerblade bearings inside.

Rollerblade bearings are cheap--about $1.25 each--and you can use a

5/16" bolt for an axle. There are a couple of nuts down inside to keep

the edge of the PVC from rubbing on the bracket. The angle brackets are

made from the same 3/4" x 3/32" bar stock as the drive axle mount. I

made mine adjustable in two axes, but after using the scope a while I

realize that I only needed the top adjustment. See a better design below.

The pipe couplings have to be reamed out a little for the bearings

to fit. You don't need the whole coupling--half or 3/4 of it will do.

The main reason to have it at all is to give the ball a nice slick PVC

surface to ride on, and to make that surface wide enough that the edge

of the bearing can't dig into the paint. (Rollerblade bearings alone are

way too narrow.)

The bearings don't have to be positioned at any particular spot on

the sphere, but bear in mind that the farther up they are, the more

they'll get in the way when you point the scope toward the horizon. I

made mine so I could tilt the scope horizontal without dropping off the

bearings, but high enough so I wouldn't push the scope off the mount

when I was slewing it.

The angle of the bearing is determined by your latitude. More on

that below.

A BETTER BEARING MOUNT: The

above bearing mount design allowed too much vibration, so in subsequent

scopes I've used a U-shaped bearing bracket that's way more

stable. There's still just one rollerblade bearing centered inside, with

a couple of nuts spun onto the bolt on either side to act as spacers to

keep the edge of the PVC from rubbing on the bracket. You can see that

the whole thing mounts directly on top of the wooden leg, rather than

hanging out in space like my first design. This is a much better design!

Go with this one.

If the ball doesn't rest on the middle of the bearing, you can put a

shim under one side of the bracket.

DECLINATION CONTROL: It turns out

there's an easy way to add declination control to a trackball. Thanks go

to Pierre Lemay for this idea.

If you mount the idler bearings so they can be moved toward or away from

the drive axle (actually I think moving them toward or away from the

celestial pole would be more direct) their motion will force the ball to

roll up or down the axle, which translates into motion in the

declination axis. You may need omnidirectonal idler bearings in order to

prevent the ball from skidding. You could also get declination control

by moving the drive axle in or out (being careful to maintain its polar

alignment while it moves). Be careful to limit the range so you don't

push the ball off the idlers!

Bearing angle

Bearing angle

You might think that the two idler bearings should be angled so they

roll more horizontally. I thought so, too, until I watched the way the

ball skidded across them. At my latitude (44 degrees north), the

bearings need to be oriented almost vertically.

Why is this? Look at the photo to the left. Think of the ball as a

globe that spins just like the Earth does (but in the opposite

direction). I've pointed the telescope at the celestial pole to make

this easier to visualize, and I've drawn latitude lines on the ball to

show where something touching it would track when the ball spins. The

bearings need to roll along those latitude lines.

Now imagine taking the telescope to Alaska, where the celestial pole

is much higher in the sky. The scope will be angled much higher, so the

bearings will need to "toe in" a ways to continue tracking lines of

latitude. Go to Hawaii and you get the opposite effect: the celestial

pole is practically on the horizon, so the bearings need to toe out in

order to follow the latitude lines.

Of course it doesn't really matter where the scope is pointed, since

the surface is a sphere. As far as the drive is concerned, it's just

spinning a globe along the celestial axis no matter how that globe is

oriented.

The easiest way to figure the correct bearing angle for your

latitude is to set up the scope with the drive axle aligned to the pole

and just watch the surface of the globe move past the bearings. Adjust

them so they're rolling rather than skidding, and you've got it.

Another way to look at it is to figure where the axis of rotation

sticks out the bottom of the ball (it's the center of that target in the

photo), and aim the axles of the idler bearings at that point.

The power/control box

For my first scope I made a hand

controller. It seemed like a good idea at the time. I thought it would

be useful to be able to speed up or slow down the tracking so I could

center objects in the eyepiece, but after using the scope a while I

realized that the fast and slow buttons weren't all that useful. The

scope is so easy to nudge manually that it's simpler to just do that if

you need to center an object. I hardly ever used the variable speed

control, either. Once it's set, it's pretty much good. So I redesigned

the whole power/control setup to what you see here, and redesigned the

circuitry inside the box.

For my first scope I made a hand

controller. It seemed like a good idea at the time. I thought it would

be useful to be able to speed up or slow down the tracking so I could

center objects in the eyepiece, but after using the scope a while I

realized that the fast and slow buttons weren't all that useful. The

scope is so easy to nudge manually that it's simpler to just do that if

you need to center an object. I hardly ever used the variable speed

control, either. Once it's set, it's pretty much good. So I redesigned

the whole power/control setup to what you see here, and redesigned the

circuitry inside the box.

It's pretty simple. It's got an on/off switch on top, a

potentiometer to adjust the tracking speed, an LED to indicate when the

power is on, and a set of six AA batteries. I put a power socket on the

side to let me plug in a 12-volt jumpstart battery, and I put a

potentiometer in series with that to drop the voltage down to match the

internal battery pack so the motor will run at the same speed whether

it's runing on the internal 9-volt battery pack or the external 12-volt

battery.

The

circuit is fairly straightforward: Power goes from the battery (either

internal or external) through the potentiometer to the motor. I wired

the potentiometer in parallel with a fixed resistor so the pot wouldn't

have to take all the current going to the motor, but at 10-20 milliamps

I doubt if that was necessary. The electrolytic capacitor provides a

little boost to start the motor when it's cold.

The

circuit is fairly straightforward: Power goes from the battery (either

internal or external) through the potentiometer to the motor. I wired

the potentiometer in parallel with a fixed resistor so the pot wouldn't

have to take all the current going to the motor, but at 10-20 milliamps

I doubt if that was necessary. The electrolytic capacitor provides a

little boost to start the motor when it's cold.

The 150K resistor in series with the LED is there to dim the LED

down to a faint glow. You just need enough light to know it's on; not

enough to be distracting. I sanded the top of the LED to diffuse it

further.

I put everything in a plastic project box and Velcroed it to the

mount underneath the motor. The AA batteries will power the motor for

many, many hours. I can go two or three years on a set of batteries, and

I use this telescope a lot.

Click on the circuit diagram for a larger image.

That's pretty much the mount. I've included a few paragraphs on the

introductory page about how to use a trackball . Here's a direct link to that discussion.

Click here to go to

the discussion of the optics.

Click here to go back to the

trackball front page.

Click here to go back to

Jerry's home page.

This is the part of the

trackball system that makes it track. The basic principle of the whole

works is to rest the spherical bottom of the telescope against an axle

that points at the celestial pole, and to rotate the axle so the sphere

turns once a day--exactly counteracting Earth's rotation. The axle is

mounted on a shuttle that can be moved along an arc, allowing adjustment

for the viewer's latitude.

This is the part of the

trackball system that makes it track. The basic principle of the whole

works is to rest the spherical bottom of the telescope against an axle

that points at the celestial pole, and to rotate the axle so the sphere

turns once a day--exactly counteracting Earth's rotation. The axle is

mounted on a shuttle that can be moved along an arc, allowing adjustment

for the viewer's latitude. The motor

The motor Latitude adjustment

Latitude adjustment Use wood for the pads, rather

than rubber, or you'll get a lot of vibration in the scope. The clamp is

just a bolt with a wooden disk on the end of it. I got fancy and drilled

a hole in the end of the bolt so I could screw the disk onto it. It's

harder than I thought to tap threads into a bolt!

Use wood for the pads, rather

than rubber, or you'll get a lot of vibration in the scope. The clamp is

just a bolt with a wooden disk on the end of it. I got fancy and drilled

a hole in the end of the bolt so I could screw the disk onto it. It's

harder than I thought to tap threads into a bolt! Bearing angle

Bearing angle